QX PACKS

- …

QX PACKS

- …

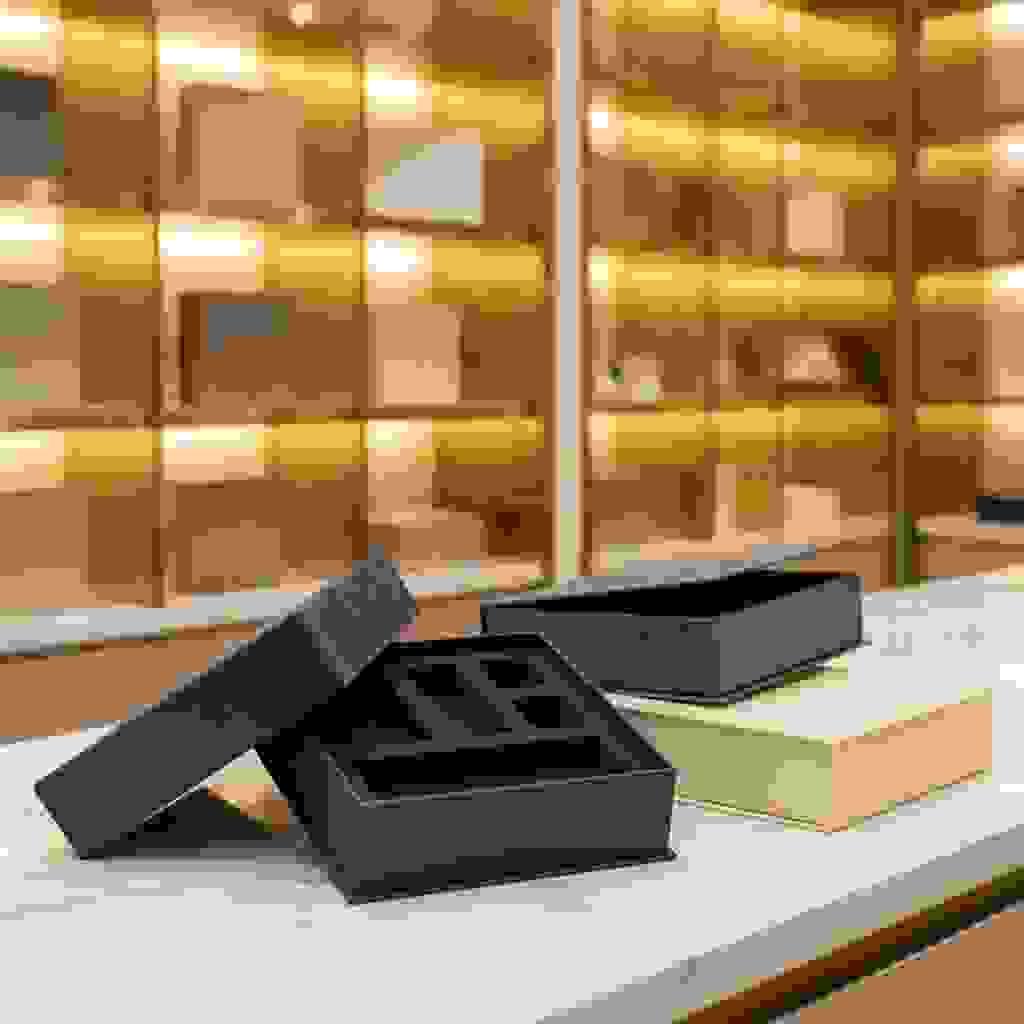

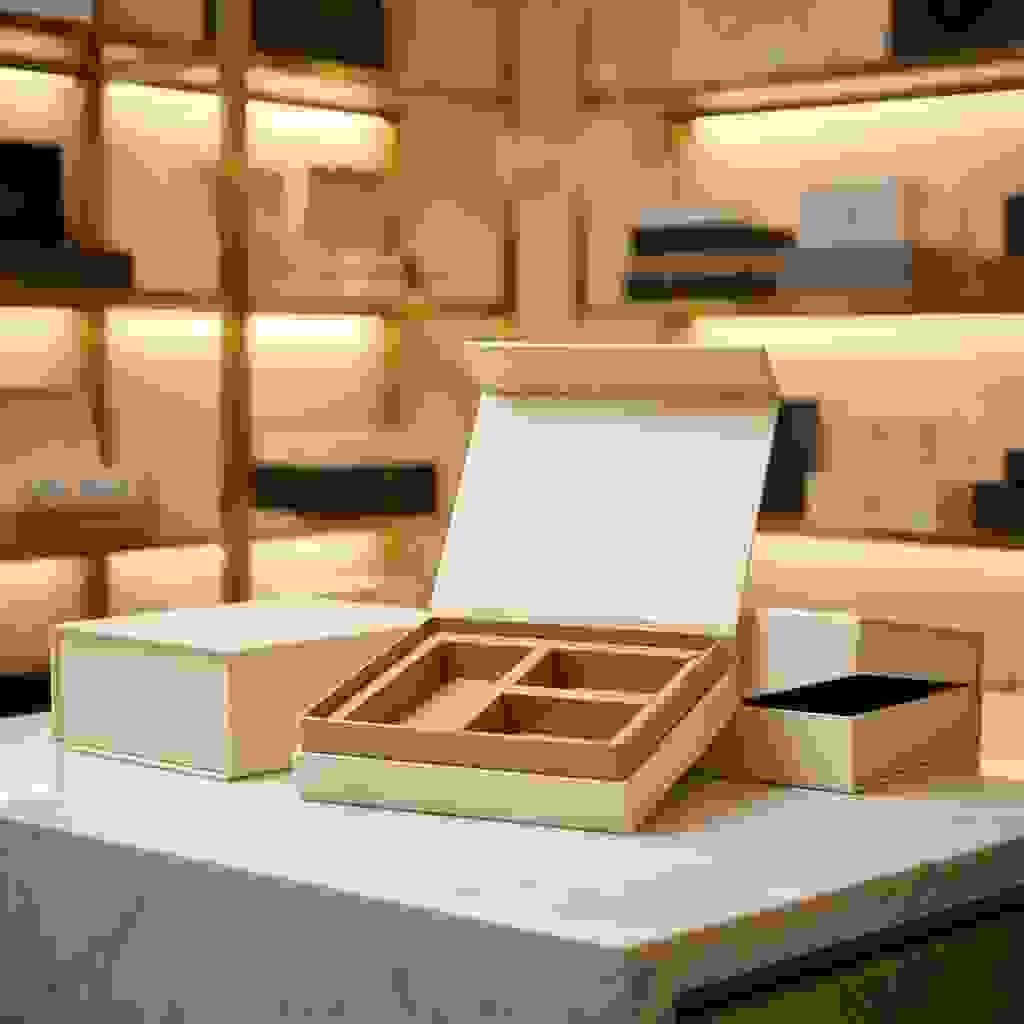

Custom Box Inserts Manufacturer in China

Precision-fit inserts to secure products and elevate presentation—EVA/foam, velvet flocking, paperboard dividers, molded pulp, and more.

What Are Custom Inserts?

Custom inserts (also called box inserts or inner trays) are fitted components placed inside packaging to hold products firmly in place. They protect items during shipping, keep sets organized, and enhance the perceived value of your brand through clean presentation and premium materials.

Key benefits

- Protects products from movement, impact, and scratches

- Keeps multi-item sets organized and display-ready

- Upgrades unboxing with premium textures and fit

- Supports retail presentation and reduces returns

Ideal for

Cosmetics, skincare, perfumes, jewelry, electronics, gifts, candles, and premium sets.Custom Insert Types

Insert Materials & Structures We Offer

EVA Foam Insert

Precision-cut EVA for strong protection and clean compartments.

PU Foam Insert

Soft cushioning for fragile items and cost-effective protection.

Velvet Flocked Insert

Luxury feel for jewelry and premium gifting with soft touch texture.

Paperboard Insert (Folded Tray)

Eco-friendly folded structures with dividers for neat organization.

Molded Pulp Insert

Sustainable molded trays for shock absorption and plastic-free packaging.

Vacuum Formed Insert (PET/PS)

Clear or tinted formed trays for retail display and precise positioning.

Why Choose Our Custom Inserts

Designed for Fit, Protection, and Brand Presentation

Accurate Fit for Your Product

Built to match your product dimensions and loading orientation.

Protection That Reduces Damage

Engineered to prevent movement and impact during transit.

Premium Look & Clean Layout

Compartments, cutouts, and alignment designed for an elevated unboxing.

Multiple Materials for Any Budget

From eco paperboard/pulp to luxury velvet and EVA.

Fast Prototyping & Sampling

Test fit and presentation before mass production.

One-Stop Packaging Integration

Insert + box matched perfectly for consistent quality and efficiency.

Customization Options

Customize materials, thickness, layout, and surface finish — tailored to your product and packaging style.

Materials

EVA/PU foam, velvet flocking, paperboard, molded pulp, PET/PS vacuum formed

Insert Structure

Single cavity, multi-compartment, dividers, layered trays, removable inserts

Surface & Details

Fabric wrap, flocking, hot stamping (no text required), pull ribbons, finger notches

Fit & Function

Drop test support, anti-scratch lining, tight tolerance cutouts, kit organization

Manufacturing Process

How We Make Your Custom Inserts

From product measurements to final inspection, each step is controlled for fit and consistency.

1Structure & Dieline Confirmation

Finalize dimensions, structure, and dielines to ensure perfect fit and smooth production.

2Rapid Sampling for

Approval

Create fast prototypes to validate look, feel, and fit before mass production.

3Material Cutting / Forming

Cut, CNC-route, die-cut, or thermoform the insert to match cavities, tolerances, and loading orientation.

4Precision Die Cutting

Clean cuts and tight tolerances for sharp edges and accurate assembly.

5Assembly & Surface Finishing

Apply flocking, fabric wrap, liners, pull ribbons, and assemble layered trays for a clean premium presentation.

6Final QC & Shipping Ready

Inspect every box and pack securely to protect quality during shipping transit.

Need Inserts That Fit Perfectly?

Send your product dimensions, weight, and packaging style — we’ll recommend the best insert material and layout, and provide a quote within 24 hours.

Company

Shenzhen QX Packs Co., Limited

Address

No. 8980 Longhua Avenue, Dafu Community, Guanlan Subdistrict, Longhua District, Shenzhen

Contact Us

+86 1372 8607 297

sales@qxpacks.com

© 2025-2026 QX Packs. All Rights Reserved.