QX PACKS

- …

QX PACKS

- …

Custom Packaging Sleeves Manufacturer in China

Upgrade any box with printed sleeves, slip sleeves, belly bands, and window sleeves for cost-effective branding and protection.

What Are Packaging Sleeves?

Packaging sleeves (also called belly bands) are paper wraps that slide over a box, tray, or product bundle. They add branding, improve shelf impact, and can also help secure inner components — without changing your existing box structure.

Key benefits

- Cost-effective branding upgrade for existing packaging

- Easy to update for seasons, promotions, or limited editions

- Adds protection against scuffs and fingerprints

- Works for boxes, trays, gift sets, and bundled products

Ideal for

Cosmetics, skincare, candles, food gifts, electronics accessories, stationery, and subscription kits.Packaging Sleeve Types

Packaging Sleeves Styles We Offer

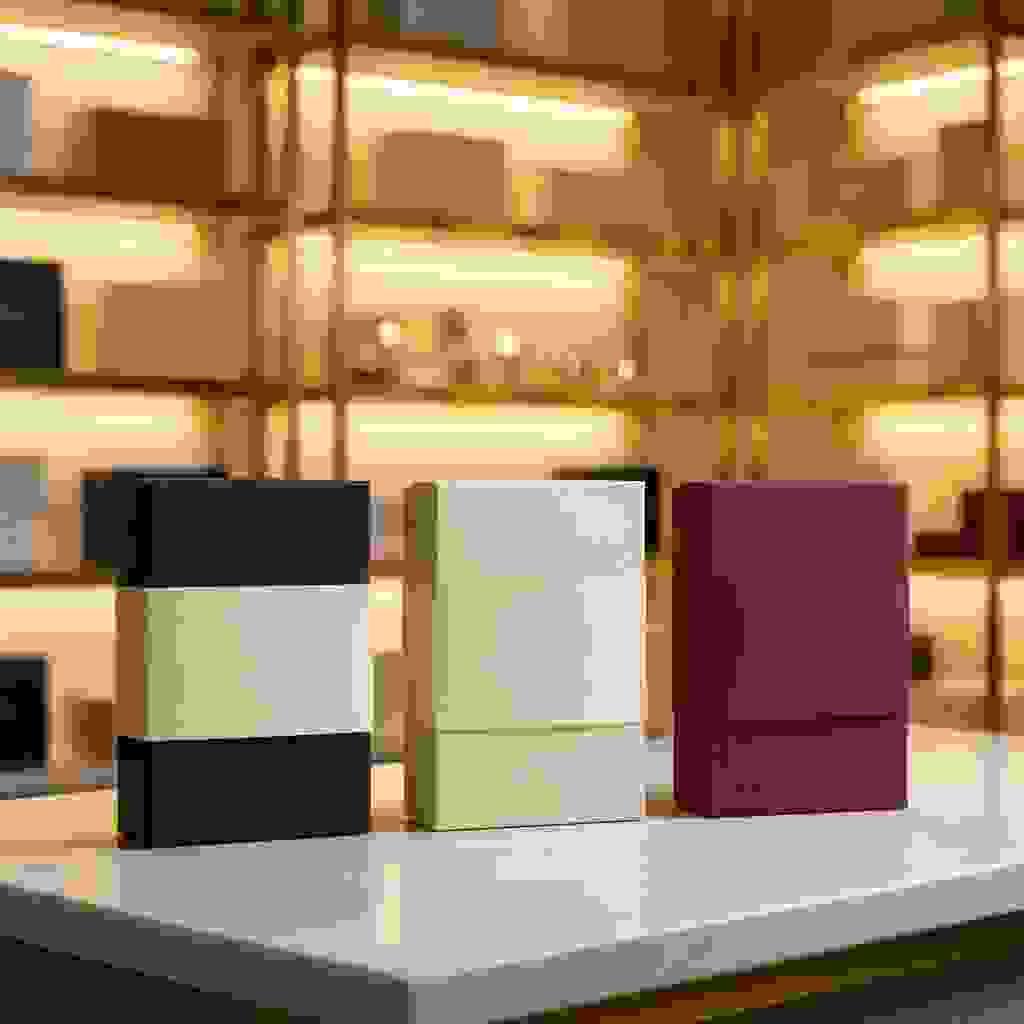

Standard Box Sleeve

A simple wrap-around sleeve for quick branding and clean presentation.

Tuck-End Sleeve

Tuck flaps help the sleeve stay secure without glue — great for retail.

Die-Cut Window Sleeve

Die-cut window packaging sleeves wrapped around rigid boxes, showing a clean window cutout on the sleeve.

Paperboard Reinforced Sleeve

Thicker material for extra rigidity and premium feel on larger boxes.

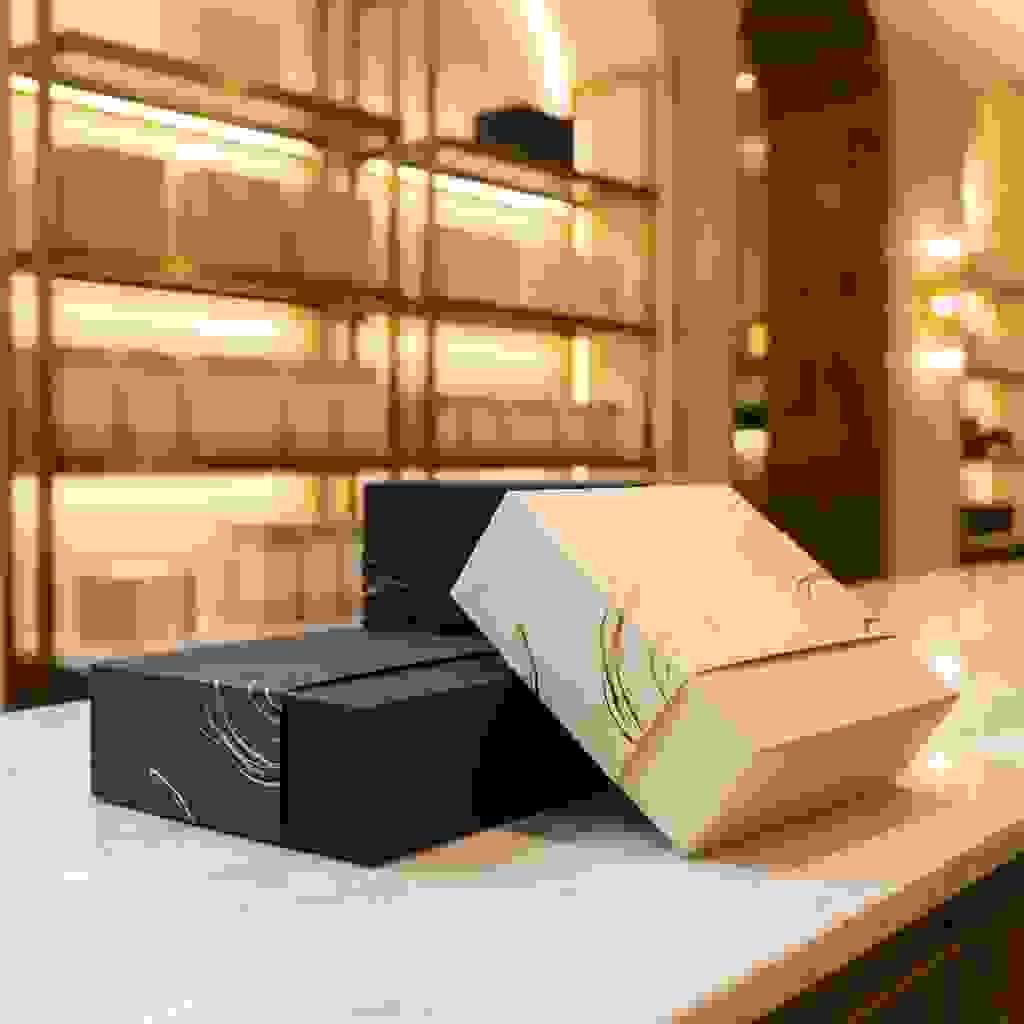

Foil & Embossed Luxury Sleeve

High-end finishes to elevate gift packaging and limited-edition launches.

Multi-Pack Sleeve/ Bundle Sleeve

Designed to hold multiple items together for sets, kits, or promotions.

Why Choose Our Packaging Sleeves

Designed for Brand Impact and Production Efficiency

Precise Fit & Smooth Sliding

Accurate dielines ensure sleeves slide on easily and stay aligned.

Color-Accurate Printing

CMYK + Pantone options for consistent branding across products.

Premium Materials Available

From coated paper to specialty textures and eco kraft.

Luxury Finishes That Stand Out

Foil, embossing, spot UV, soft-touch lamination, anti-scratch coating.

Low MOQ & Fast Sampling

Quick prototypes to confirm fit, artwork placement, and finishing.

Factory-Direct Quality Control

Stable production process for consistent results at scale.

Customization Options

Choose materials, printing, finishes, and structural details — tailored to your box and branding.

Materials

Coated paper, kraft paper, specialty papers, paperboard (reinforced)

Printing

CMYK offset/digital, Pantone spot colors, inside/outside printing

Finishing

Matte/gloss lamination, soft-touch, foil, emboss/deboss, spot UV, anti-scratch

Structure Details

Window cutouts, tuck locks, tear strip, thumb notch, multi-pack sleeves

Manufacturing Process

How We Make Your Packaging Sleeves

From dieline to finishing, each step is controlled for clean edges and perfect fit.

1Structure & Dieline Confirmation

Confirm sleeve dimensions, overlap, and folding lines to ensure smooth sliding and a perfect fit.

2Rapid Sampling for

Approval

Produce quick prototypes to validate size, artwork placement, and sleeve tightness before mass production.

3Color-Accurate Printing

& Lamination

Print with consistent color control and apply protective lamination for a premium, durable surface.

4Precision Die Cutting

Die cut clean edges and crease accurately to keep corners sharp and folds smooth.

5Finishing (Foil / UV / Emboss)

Apply luxury finishes with precise registration to enhance branding and shelf impact.

6Final QC & Shipping Ready

Inspect fit, color, and finishing, then pack securely to protect sleeves during transit.

Ready to Create Your Custom Packaging Sleeves?

Send your box size (L×W×H), sleeve coverage, material/finish ideas, and quantity — we’ll reply within 24 hours with a quote and dieline suggestions.

Company

Shenzhen QX Packs Co., Limited

Address

No. 8980 Longhua Avenue, Dafu Community, Guanlan Subdistrict, Longhua District, Shenzhen

Contact Us

+86 1372 8607 297

sales@

© 2025-2026 QX Packs. All Rights Reserved.